TECNOLOGIC 3® is continuously designing and developing new and tailor-made application equipment to guarantee high quality performances so as to meet any of our customers’ needs. TECNOLOGIC 3® machines are designed with automated processing parts and dedicated quality checks to prevent errors when associated with a manual application.

Upon request the service will include dedicated vision inspection devices for the in-line process checking and product quality control.

Equip the machine with following options, upon customer request, and with more than just a normal PLC:

- Display units/s for integrated operation

- Programming directly on the device

- Display and editing of message text/variables on the device

Technical assistance and dedicated service will guide you on all the initial phases of the project. The Tecnologic 3 machine is based on the TECNOLOGIC 3® patent.

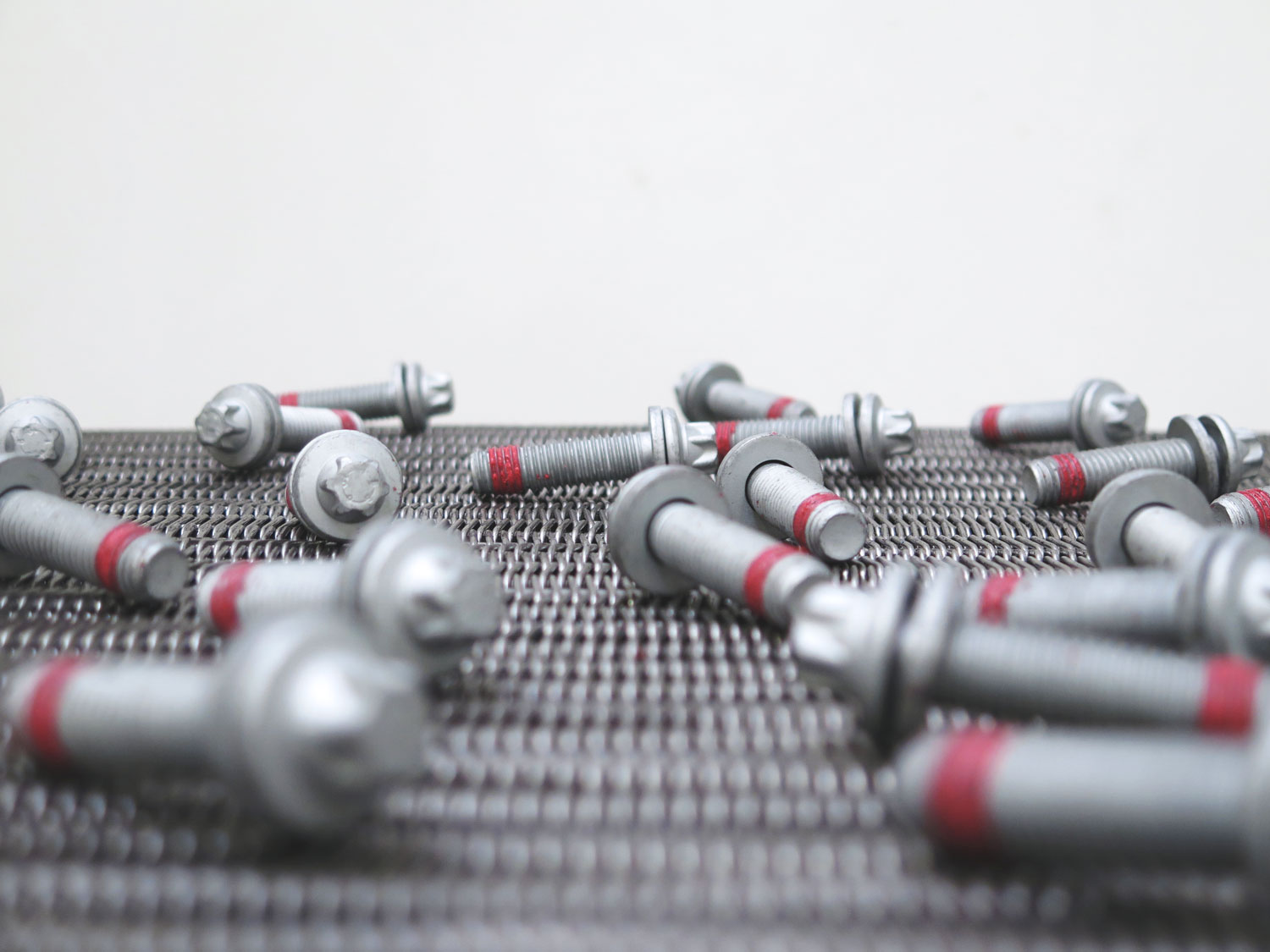

Pre-applied strong and medium blockers. They block and seal any threaded connection, can be applied to all types of metals and some plastics. During screwing and tightening of the threaded parts, the microcapsules break and with the resins are distributed between screw and lead screw; once polymerization is complete, the product reaches its blocking and sealing power, resulting in excellent resistance to loosening, stress and vibrations.

Strong sealants that can be applied on any threaded connection (cylindrical / cylindrical and cylindrical / conical), on all types of metal and on most plastics. During the coupling of the threaded parts, the sealant is distributed eliminating the interference of the threads, ensuring high sealing power for liquids and pressures.

Strong sealants that can be applied on any threaded connection (cylindrical / cylindrical and cylindrical / conical), on all types of metal and on most plastics. During the coupling of the threaded parts, the sealant is distributed eliminating the interference of the threads, ensuring high sealing power for liquids and pressures.

Suitable for protecting the threaded parts of any threaded connection from adhesion of primers, welds, the low temperatures of the application allow the integrity of the coating and the hardness of the thread.

TECNOFREN® pre-applied, makes any threaded connection Braking / Sealing, Adjustable and Reusable. During screwing, TECNOFREN® is distributed between the thread and the nut screw and eliminates the spaces between the threads, increasing the metal-metal contact and opposing a tenacious and durable resistance to loosening and vibrations. TECNOFREN® takes advantage of the elastic deformation properties of polyamide.

Friction coefficient regulators, dry to the touch, are ideal for self-tapping screws, for the prevention of cold welds and to reduce and simplify assembly times. They can be combined with our Locking, Sealant and Self-locking products. Lubricants and Protective Agents with efficient anti-corrosion power and perfect adhesion to the surfaces guarantee protection in areas subject to high humidity levels and are ideal for long term warehouse storage. They are perfectly adapted to sea transport, and can be applied to a wide range of metals and plastics.

For product information, please contact Tecnologic3® by email at

tecnologic3@tecnologic3.it

Ensures the locking of threaded couplings of all types.

Ensures locking in high temperature threaded couplings

It ensures a high separation torque

Ensure breakaway torque with low friction value.

Eliminate pollution problems due to the use of solvents.

Facilitate the assembly of finished pieces: locking, fluid tightness, cost reduction, internal and external pieces are welcome to operators.

Pre-applied Benefits

TECNOLOGIC® is a pre-applied processes series which adheres a line of acrylicbased sealing materials manufactured by TECNOLOGIC 3® to the underhead of fasteners. TECNOLOGIC® processed fasteners negate the need for additional O-rings, gaskets, or sealing washers. When the fastener is installed, TECNOLOGIC® conforms to surface dimensions and fills voids between mating parts, forming a robust seal.

Saves Time:

Pre-Applied TECNOLOGIC 3® fasteners can be automatically fed through standard feeding devices– speeding up your process and improving productivity.

Saves Money:

The Pre-Applied TECNOLOGIC 3® process is less expensive than other underhead fastener sealing methods. It also eliminates the need for costly O-rings and nylon washers.

Quality Control:

Pre-Applied TECNOLOGIC 3® coats fasteners to specification, ensuring measurable and consistent performance.

Reusable:

TECNOLOGIC 3® processed fasteners are removable and reusable.

Corrosion Resistance:

The materials used in the Pre-Applied TECNOLOGIC 3® process isolate dissimilar metals which helps to reduce galvanic corrosion.

Pre-applied Service

Step 1 - Material Selection: Our sales and R&D staff will help you find or custom formulate a material to meet your performance specifications.

Step 2 - Shipping: Once a selection has been made, have your fasteners shipped to one of our worldwide processing centers.

Step 3 - Processing: Utilizing custom, high speed equipment, we apply the selected material to your exact specification.

Step 4 - Delivery: Once processing is complete, parts are shipped back ready for distribution or assembly.